In what can be described as a major breakthrough, scientists of Materials Research Centre at Bengaluru-based Indian Institute of Science have developed enzymes that can effectively degrade toxic chemicals in industrial wastewater in the presence of sunlight. This discovery could be very vital as according to a United Nations’ report in India “only 60 per cent of industrial waste water, mostly large scale industries, is treated.”

The enormity of the industrial waste water pollution problem can be gauged when one looks at the report of Karnataka State Pollution Control Board. It states that 68 lakes in Bengaluru are under Category D which are unfit for drinking and bathing even after treatment and 40 are under E that is they are not even suitable for fisheries.

Water resources are classified as A, B, C, D and E based on water quality parameters released by the Central Pollution Control Board. In fact, according to CPCB, Bengaluru lakes can be used for industrial cooling, controlled waste disposal, irrigation and propagation of fisheries.

Enzymes are proteins that can catalyse a large number of biological reactions in living beings. The issue with practical use of natural enzymes is that they are greatly hindered by inherent limitations. The researchers at IISc have created in the laboratory nano-sized enzyme mimetics or nanozymes that can mimic natural enzymes.

Need for nanozyme

Production of natural enzymes entails several issues including their complex production procedures, high costs, difficulties in recycling, and they being easily damaged — all of which make their use unpractical. Subinoy Rana, Assistant Professor at MRC in the IISc Press release stated that inherent limitations of natural enzymes “include sensitivity to denaturation (breakdown/damage), complex production procedures, high costs, and difficulties in recycling.”

Apart from this mass production of enzymes is an expensive and time-consuming process. Laccase, for example, which is a natural enzyme used for degrading phenols in industries, is extracted from a fungus called white rot and the amount of this which can be produced is dependent on the quantity of the fungus that is available at a given time. “It’s a long process and it’s difficult to make them in more than milligram amounts,” Rana observed. Apart from this storage of natural enzymes is difficult as they are temperature-sensitive and require cooler temperatures, often as low as -20°C.

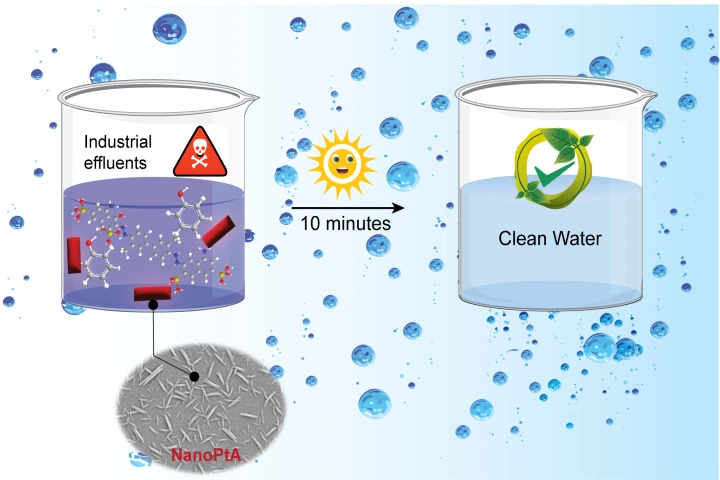

Manufactured in the lab, the nanozymes can mimic natural enzymes. In their study, the IISc scientists synthesised a platinum-containing nanozyme called NanoPtA, which can be converted into powder form for industrial use. This imitates the function of oxidases – natural enzymes that remove hydrogen from substrates in the presence of oxygen to give water. It is also strong because of its ability to withstand a range of pH and temperature changes.

With NanoPtA coming in contact with wastewater it degrades pollutants present in it by oxidising them in the presence of sunlight, thereby reducing the toxicity of wastewater.

Further the research team tested the nanozyme’s effect on common effluents that pollute water, like phenols and dyes and found that it can degrade even small quantities of phenols and dyes within ten minutes when placed under sunlight.

The NanoPtA complex was quite stable, lasting for up to 75 days at room temperature. Sharing details on this aspect Rana said: “Proteins are generally stored at -20°C or 4°C, but in this case, it can be stored at room temperature.”

Other applications

The team suggested that the nanozyme can also have applications in healthcare. They tested its ability to oxidise neurotransmitters like dopamine and adrenaline. According to Rohit Kapila, a PhD student at MRC: “This is important because these neurotransmitters are associated with Parkinson’s, Alzheimer’s disease, and cardiac arrest.” He added that measuring these neurotransmitters using such nanozymes can potentially be a useful diagnostic tool for neurological and neurodegenerative diseases, he adds.

The team believes that the nanozyme can be manufactured in large quantities on an industrial scale and thus they plan to patent it. They are also looking at less expensive metal alternatives to platinum in the nanozyme complex.