On 15 August 2014, Prime Minister Modi made an appeal from the ramparts of Red Fort – “Come, Make in India”. Sell anywhere in the world but manufacture here! We have skill, talent, discipline, and determination! Satellite or submarine, “Come, Make in India”. Raising the pitch further, on 12 May 2020, he made the clarion call for Atmanirbhar Bharat (Self-reliant India).

“Win Indian Wars with Indian Solutions” was the mission undertaken by the author as Deputy Chief of the Army Staff, to accomplish the ‘Make in India’ objectives for defence of the country. Focused towards achieving self-reliance in defence, an unprecedented outreach programme was undertaken with extensive Army, Industry and Academia workshops all across the country. This was followed by visits to border areas, capability demonstrations and publication of problem statements to mobilise participation of industries and academic institutions towards achieving the mission. To institutionalize the process the Army Design Bureau was created in 2016.

Atmanirbhar Bharat in Defence

To achieve self-reliance in defence some of the major initiatives undertaken by the Government are given below:

Four ‘positive indigenisation lists’ (import embargo) comprising 411 defence systems and equipment have been issued in the last three years, with timelines beyond which the items would be procured from indigenous sources only.

Three positive indigenisation lists comprising 3738 sub-systems, assemblies and components have been issued by the Defence Public Sector Units for indigenisation and procurement from the private sector.

Defence Research & Development has been opened for industry, start-ups, and academia with 25 percent of defence R&D budget earmarked, to promote development of defence technology in the private sector.

Defence Offset Policy is being regularly updated to better leverage global capital acquisitions to develop Indian defence industry and augmenting capacity for research, design, and development. The offset obligations of FOEMs to be discharged over the period 2008 to 2033 is estimated at approximately US$ 13.52 billion.

Impetus for Make projects to increase private sector participation in indigenous design and development of equipment, systems, major platforms, upgrades, and import substitutions. Make projects are broadly classified as Make-I (Government Funded) for platforms and systems, Make-II (Industry Funded) for components and subsystems, and Make-III for import substitution.

Innovation for defence excellence (iDEX) meant to promote innovation and startups participation in defence.

Two defence industrial corridors have been set up in Uttar Pradesh and Tamil Nadu. Many state governments have announced their incentives for industries in defence and aerospace sector.

Hon’ble Prime Minister Shri @narendramodi announces setting up of Defence Industry Corridor in Uttar Pradesh covering Aligarh, Agra, Jhansi, Chitrakoot, Kanpur and Lucknow at @InvestInUp .#MakeInIndia4Defence #UPInvestorsSummit #MakeInIndia@PMOIndia @nsitharaman pic.twitter.com/jOM0kZxZ25

— रक्षा मंत्री कार्यालय/ RMO India (@DefenceMinIndia) February 21, 2018

To encourage start-ups and MSMEs to invest in defence manufacturing, Rs.1500 Crores has been earmarked in the budget for Financial Year 2023-24.

To make India self reliant in defence manufacturing, Modi Government has announced setting up of two defence production corridors. One of these corridors is planned to come up in Uttar Pradesh while the other will be in Tamil Nadu#TamilNaduDefenceCorridor pic.twitter.com/QbyZaqRR3y

— Mayank(मयंक) (@MODIfiedMayank) March 16, 2018

Liberalisation of Foreign Direct Investment (FDI) allowing 74% FDI under automatic route.

Drive to increase defence exports.

Defence Production Goals

The Government is committed to transform India into a defence manufacturing hub, with the stated objective of achieving a “turnover of Rs 1,75,000 Crores (US$ 25Bn) including export of Rs 35,000 Crore (US$ 5 Bn) in Aerospace and Defence goods and services by 2025.” This entails enhanced participation of the private sector. Size of the defence industry is currently estimated to be around Rs 95,000 Crores.

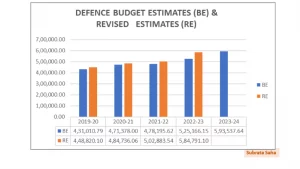

Defence Budget and Domestic vis-a-vis Foreign Procurement

Defence Budget allocations from Financial Year 2019-20 to 2023-24 in Crores of Rupees is given in the chart below:

The capital outlay for defence services from Financial Year 2019-20 to 2023-24. has gone up from Rs. 80,959.08 crores to 1,32,301.27.

The ratio of domestic to foreign procurement for Financial Year 2023-24 has been earmarked in the ratio of 75:25, the 75% for procurement through domestic sources being Rs. 99,223.03 crores, and 25% i.e., Rs. 33,078.24 crores for foreign procurement.

Value of Defence Production

The value of defence production has been increasing progressively, albeit slower than required to achieve the stated objective of Rs 1,75,000 Crores by 2025. The value of defence production was Rs 79,071 crores in 2019-2020, Rs 84,643 crores in 2020-21, and touched Rs 94,845 crores in 2021-22.

Success Stories in Atmanirbharta

Some significant and successful projects of indigenous production include: 155mm Artillery Gun system ‘Dhanush’, Advanced Towed Artillery Guns (ATAGs), Light Combat Aircraft ‘Tejas’, Surface to Air Missile system ‘Akash’, Main Battle Tank ‘Arjun’, Advanced Light Helicopter, High Mobility Trucks, INS Kalvari, INS Khanderi, INS Chennai, Anti-Submarine Warfare Corvette (ASWC), Bi-Modular Charge System (BMCS) for 155mm Ammunition, Medium Bullet Proof Vehicle (MBPV), Weapon Locating Radar (WLR), Integrated Air Command and Control System (IACCS), Software Defined Radios (SDR), Lakshya Parachute for Pilotless Target Aircraft, Opto Electronic Sights for Battle Tanks, Water Jet Fast Attack Craft, Inshore Patrol Vessel, Offshore Patrol Vessel, Fast Interceptor Boat, Landing Craft Utility, 25 T Tugs, etc.

While some of these platforms and systems are top of the line, others are undergoing improvements. The important point being the armed forces are much more open to handholding indigenous development and accept ‘spiral development’ – acquire and improve concomitantly.

Decisive Shift in Defexpo Themes

Defence exhibitions in the past were more of an opportunity for foreign suppliers to exhibit their products in India. The theme has been progressively shifted to exhibiting domestic defence products. The DefExpo-2022 with its theme as ‘Path to Pride’, was exclusively organised for Indian defence companies. It witnessed more than 15 lakh visitors and saw the highest ever participation of 1340 exhibitors. The exhibition had visitors from 80 friendly foreign countries.

In addition to providing a platform for exhibiting products, the DefExpos are also being utilised for progressing strategic relations. The second edition of the India Africa Defence Dialogue (IADD) was held at the DefExpo-2022 where 50 African countries participated reflecting the significance of the India-Africa engagement in defence and security. An Indian Ocean Region (IOR)+ Defence Ministers’ Conclave was held during DefExpo-2022 with participation of 41 countries.

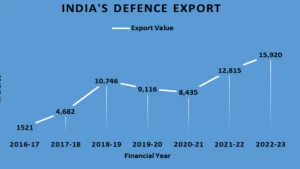

Defence Exports

India’s defence exports have increased tenfold, from a value of Rs 1521 crores in 2016-17 to Rs 15920 crores in 2022-23. There is immense scope for improvement though, as most of the current export value is from components and spares. The DefExpo 2022 witnessed some interest in larger systems like helicopters, fighter aircrafts, missile systems, weapon locating radars from friendly foreign countries. The defence export values will improve further as India exhibits its products in defence exhibitions, joint exercises and India’s missions abroad transform further from an import to export orientation.

Collaboration for Emerging Technologies and Critical Minerals

India is going in for strategic partnerships with likeminded nations for cooperation in emerging technologies such as artificial intelligence, quantum technologies, next gen telecommunications, space, high performance computing and semiconductor supply chains. All of these have significant defence applications. The key has to be co-development and coproduction.

According to a Rand Report of 2022, 18 of the 37 minerals relevant to defense applications are concentrated in China. Only 5 defense-related minerals are concentrated in the United States, Australia, and Canada. 14 more are concentrated in countries with strong diplomatic and economic relationships to China, including Russia, Brazil, and Belt and Road Initiative (BRI) countries. While India explores its own mineral reserves, it should seek collaboration with countries for critical minerals and develop capabilities for processing minerals.

Going Forward – Three Fundamentals: R&D, Quality & Acquisition

Defence R&D

There have been some great success stories with DRDO, nonetheless the potential of Defence R&D in the country has hardly been exploited to anywhere near its capabilities. India’s defence ecosystem is very centralized, and predominantly government run. The total procurement of DRDO designed equipment over a period of 11 years from 2011 to 2021, was just about equal to the allocation of one year’s capital procurement. In the last six to seven years DRDO has taken several initiatives to expand the participation of private sector and academia in Defence R&D. Initiatives like encouraging private sector Development cum Production Partner (DcPP) have had a positive impact on DRDO’s deliverables. Setting up of Joint Advanced Technology Centres (JATC) at academic institutions have begun to show results, even though as to how the project outcomes will be linked to the procurement process isn’t clear.

The DRDO itself is over-stretched by undertaking projects from very high-end strategic R & D to low-end projects, some of which do not really need to be executed out of defence R & D budget. The Union budget 2022 has announced an allocation of 25% defence R & D Budget for academia and private sector. Projects sanctioned through this budget, should be guided by the defence capability development plan, and defence technology development plan. Ownership of projects must be with the Services, and lead to timely procurement. Only then will this initiative effectively tap the potential of innovators, start-ups and MSMEs.

Make Projects – Design & Development

The approach to Make-I (Government Funded) projects for platforms and systems should change from a procurement perspective to primarily a Design and Development perspective. In doing so, the risk of failure of a project should be taken in its stride, and lessons learnt for follow-on projects. The timeline for sanction of the project has to be compressed so that the services do not have to modify their PSQRs even before initiating the project, and industry can expect timely return of investment.

Service HQ must take ownership of their Make projects, and accept spiral development, with scope for technology infusion as the system progresses. The IPR should be jointly held, and export promotion should be a part of the project plan. In case two Development Agencies (DA) are not available the project should go ahead with a single DA, with appropriate benchmarking of the cost by involving costing specialists in addition to other stakeholders. Depending on the significance of the project, the Defence Acquisition Council (DAC) should be given flexibility to allocate a higher percentage of funding than 70%, as currently stipulated.

Quality Standards

Private sector participation in Indian defence industry is still expanding and maturing. In the past, there have been quality issues with products including accidents., In order to provide further impetus to domestic manufacturing, since August 2019 four positive indigenisation lists have been promulgated, banning import of the listed equipment by indicated time frames. Most of the equipment given in the positive indigenisation lists are still in development phases. Safeguarding quality is essential not only for India’s national security, but also for gaining acceptability in global export market and safety of the users.

Industries expressing interest in participating in Defence should mandatorily have to go through a defined process for approval of their Quality Management System. This approval should be based on inspections of the industry processes and outcomes by the defence Quality Assurance agencies. Likewise, appropriate policies and mechanisms have to be built in for start-ups selected for defence projects.

Procurement Management

The procurement mechanism is too diversified, inadequately connected and too tedious. There are too many stakeholders involved in the process, operating from different silos – multiple directorates in Service HQs, QA agencies, HQ IDS, multiple stages in DG Acquisition’s office, DRDO, DDP, MOD Finance and competent authorities for approval. The process is too repetitive, too much time is spent in examination, raising and reconciling observations.

There is a need to adopt an integrated fully accountable procurement agency, comprising specialists in services, project experts, technological experts, QA, costing and financial experts should deal with procurements. The procurement agency should be independent of all other departments of MoD and report directly to the Raksha Mantri.

The Defence Sector was opened for direct private sector participation in 2000, but the real impetus came after 2015-16. With ‘positive indigenisation lists’, defined budgetary allocation for procurement from domestic defense industry, strategic partnership, export promotion, corporatisation of ordnance factories, the policy environment has never been so conducive. Some large private industries participating directly in defence contracts since 2000, or earlier as subsidiaries of DPSU/OFs and DRDO, have leveraged the encouraging government policies and improved their deliverables substantially. However, there is still a lot of scope to involve more industries by helping them to shed their inhibitions to participate in defence, particularly MSMEs.

With improved R&D, quality assurance and active collaboration of our academia and industry, India’s armed forces will ‘Win India’s Wars with Indian Solutions’.

Also Read: Govt okays new list of 928 defence items to be made in India under Aatamnirbhar scheme

(The author is former Deputy Chief of Army Staff and Member, National Security Advisory Board. He was the Founding DG of Society of Indian Defence Manufacturers)